Adaptive Diagnostics and Prognostics (ADAPT) Toolbox

Why ADAPT?

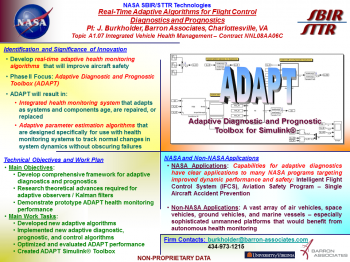

Model-based machinery diagnostic and prognostic techniques depend upon high-quality mathematical models of the plant. Modeling uncertainties and errors decrease system sensitivity to faults and decrease the accuracy of failure prognoses. However, the behavior of many physical systems is poorly known and may change slowly over time as the system ages. These changes may be perfectly normal and not indicative of impending failures; however, if a static a priori model is used, modeling errors may increase over time, which can adversely affect health monitoring system performance. Moreover, manufacturing tolerances and environmental impacts may cause variations in unfaulted system dynamics between nominally identical plants. These variations significantly complicate practical, widespread application of model-based diagnostic techniques.

Clearly, one method to address these problems is to employ a model that adapts to system uncertainties and slow changes over time. The risk in using data-driven models that learn online to support model-based diagnostics is that the models may “adapt” to a system failure, thus rendering it undetectable by the diagnostic algorithms. An inherent trade-off exists between accurately tracking normal variations in system dynamics and potentially obscuring slow-onset failures by adapting to failure precursors that would be evident using static models.

In practice, the behavior of many physical systems is complex, encompasses a large operating regime, and is subject to external disturbances and noise. Exhaustive data collection to develop highly accurate a priori models of unfaulted system behavior may be costly and impractical in many applications. It would be highly valuable to utilize an automated, readily portable set of integrated adaptive diagnostic and control algorithms for a large class of dynamic systems.

An adaptive diagnostic and prognostic system has three main components: (1) online system identification / parameter estimation; (2) adaptive modeling/filtering/observation, and; (3) diagnostic and prognostic algorithms and logic. ADAPT contains all of the functionality necessary to assemble adaptive systems suitable for a wide range of diagnostic and prognostic applications.

System Requirements:

ADAPT is Simulink Toolbox, which requires, at a minimum, a license for Matlab and Simulink products from The Mathworks – Release 2007b or later.

System Usage:

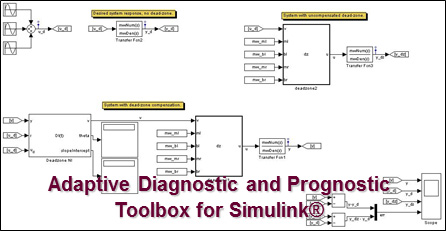

The ADAPT toolbox provides advanced system health monitoring algorithms in the form of Simulink block components. These components may be used to develop health monitoring applications with the Simulink modeling tool. The applications can be tested and refined within the high-fidelity Simulink modeling environment. After verification, the Real-Time Workshop code generation tool may be used to generate deployable C language code for integration in online real-time health monitoring systems. The ADAPT algorithms provide out-of-the-box diagnostic capabilities that are applicable to a wide range of health monitoring problems.

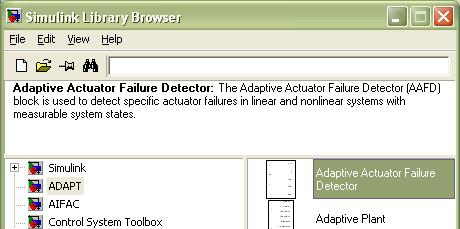

ADAPT Toolbox in Simulink Library Browser

All ADAPT blocks are masked, providing a dialog for entering block parameters, including prompts and help text. Each toolbox component has an integrated help page. This page is accessible by selecting the “Help” menu item on the component’s right-click context menu.

The ADAPT Toolbox contains over a dozen Simulink blocks to aid in the design of health monitoring systems for a variety of linear plants, nonlinear plants, and plants with and without full state measurement.

For pricing and ordering information, contact sales@barron-associates.com